Confined spaces, such as tanks, tunnels, and maintenance holes, can be treacherous due to their limited airflow and the potential for harmful gas buildup or oxygen depletion. These conditions pose severe risks to workers, emphasizing the critical need for proper ventilation.

Over 15 years, there were 18 fatalities in confined spaces in British Columbia, averaging more than one per year, according to statistics from WorkSafeBC. Some estimates suggest that over 100 such deaths occur across Canada annually.

In this blog, we'll explore why proper confined space ventilation is crucial for ensuring workers' safety.

Ventilation plays a crucial role in removing hazardous gases, vapors, and contaminants from confined spaces. This ensures that workers can breathe easily and avoid exposure to harmful substances, underlining the vital importance of your work in maintaining their safety.

We'll discuss the different methods and techniques for ventilating confined spaces, including natural ventilation, mechanical ventilation systems, and portable ventilation equipment.

Each method has its advantages and considerations, and we'll explore how to choose the right ventilation solution based on the specific requirements of the confined space and the tasks being performed.

Additionally, we'll highlight the importance of proper training and safety protocols for working in confined spaces, including procedures for testing air quality, monitoring hidden workplace hazards, and implementing emergency response measures.

Factors Influencing Ventilation System Selection

Selecting the right ventilation system for confined spaces includes critical factors.

From the size and shape of the space to the hazards present and environmental conditions, each element plays a vital role in determining the most effective ventilation solution.

Here are the main factors that influence ventilation system selection:

-

Size and shape of the confined space

-

Type and level of hazards present

-

Duration of work in the confined space

-

Environmental conditions surrounding the confined space

Let's explore each of these factors in detail so you can select the perfect fit!

1. Size and shape of the confined space

The confined space's size and shape directly influence the ventilation system's selection. Larger spaces need more powerful ventilation equipment to ensure adequate air exchange.

Additionally, irregularly shaped spaces may require careful planning to effectively distribute airflow and prevent stagnant air pockets where hazardous gases could accumulate.

Understanding the dimensions and layout of the confined space is crucial for determining the type and placement of ventilation equipment to maximize air circulation and maintain safe working conditions for personnel.

2. Type and level of hazards present

The type and level of hazards in the confined space are essential for ventilation system selection.

Workplace hazards, such as toxic gases, combustible vapors, or low oxygen levels, require specific ventilation solutions to mitigate risks effectively.

Ventilation systems must remove or dilute hazardous substances to safe levels, ensuring the health and safety of workers entering the confined space.

Additionally, the concentration and nature of hazards dictate the airflow requirements and ventilation rates necessary to maintain a safe working environment.

Ventilation rates refer to the amount of air that needs to be circulated within the confined space to maintain safe air quality. Understanding these rates is crucial for designing and selecting ventilation systems that can effectively mitigate confined space hazards.

3. Duration of work in the confined space

The duration of work in the confined space impacts ventilation system selection. For short-term tasks, temporary or portable ventilation solutions may suffice, providing flexibility and ease of setup.

In contrast, long-term projects may require more permanent ventilation installations to sustain safe air quality over extended periods.

Factors such as maintenance needs, energy consumption, and operational costs must be considered when choosing ventilation systems based on the duration of work.

Adequate ventilation is essential for ensuring workers' well-being throughout their activities in the confined space, regardless of the time spent inside.

4. Environmental conditions surrounding the confined space

Environmental conditions surrounding the confined space, including temperature, humidity, and external airflow, influence ventilation system effectiveness.

Variations in these conditions can affect ventilation equipment performance and airflow distribution within the confined space.

For example, extreme temperatures or high humidity levels may impact ventilation system efficiency or pose additional challenges to maintaining safe air quality.

Understanding and accounting for these environmental factors are crucial for selecting ventilation systems that effectively mitigate confined space hazards and maintain optimal working conditions inside the confined space, regardless of external conditions.

Types of Confined Space Ventilation Systems

Understanding the various ventilation systems available for confined spaces is crucial for ensuring proper air quality and worker safety.

These systems can be broadly categorized into natural ventilation methods, which rely on natural airflow, and mechanical ventilation systems, which utilize mechanical equipment to circulate air.

Natural ventilation methods

Natural ventilation methods rely on the natural flow of air to provide air exchange within confined spaces.

These methods utilize openings, such as doors, windows, vents, or other apertures, to facilitate air movement into and out of the confined space.

Unlike mechanical ventilation systems, natural ventilation does not require mechanical equipment to circulate air.

Instead, it utilizes the confined space's existing features and external environmental factors, such as temperature differentials or wind patterns, to promote airflow.

Natural ventilation is often considered a cost-effective and straightforward solution for air circulation in confined spaces.

By harnessing natural airflow, these methods can help remove stale air and potentially harmful contaminants from the confined space, improving air quality and ensuring the safety of workers.

However, the effectiveness of natural ventilation methods may vary depending on factors such as the size and configuration of openings, external weather conditions, and obstructions that may impede airflow.

Openings and airflow

In natural ventilation methods, airflow effectiveness within confined spaces is directly influenced by the size, location, and number of openings.

Openings, such as doors, windows, vents, or ducts, serve as pathways for fresh air to enter and stale air to exit the confined space.

The placement of these openings is crucial, as it determines the direction and intensity of airflow within the space.

Properly positioned openings allow for efficient air exchange, promoting circulation and ensuring adequate ventilation.

Adequate airflow is a key component of effective ventilation systems. It helps remove stagnant air and pollutants, maintain air quality, and minimize the risk of hazardous conditions within the confined space.

In other words, airflow is the movement of air within a confined space, and it's crucial for ensuring the safety and well-being of workers.

Factors such as the size of openings, their proximity to potential sources of contamination, and external environmental conditions all influence the effectiveness of airflow in natural ventilation methods.

By understanding the relationship between openings and airflow, workers and safety personnel can optimize natural ventilation strategies to create safer working environments within confined spaces.

Regular inspection and maintenance of ventilation systems, including the openings used in natural ventilation methods, are essential to ensure their functionality and effectiveness in promoting airflow and ventilation.

This ongoing maintenance is not just a chore but a crucial part of ensuring the continued safety of workers in confined spaces.

Wind-driven ventilation

Wind-driven ventilation is a natural ventilation method that harnesses the power of wind to promote airflow within confined spaces.

This method relies on external wind pressure to drive air movement through openings in the confined space, facilitating air exchange and promoting ventilation.

The effectiveness of wind-driven ventilation depends on several factors, including the size and location of openings, the direction and intensity of the prevailing winds, and the configuration of the confined space.

Properly positioned openings, such as vents or windows, allow wind to be captured and channeled into the confined space, promoting airflow and helping to remove stale air and contaminants.

Wind-driven ventilation is often considered a cost-effective and energy-efficient solution for ventilation in confined spaces, as it does not require mechanical equipment or power sources.

However, its effectiveness may be limited in areas with inconsistent or insufficient wind conditions.

Additionally, proper planning and design are necessary to optimize wind-driven ventilation systems and ensure adequate ventilation within confined spaces.

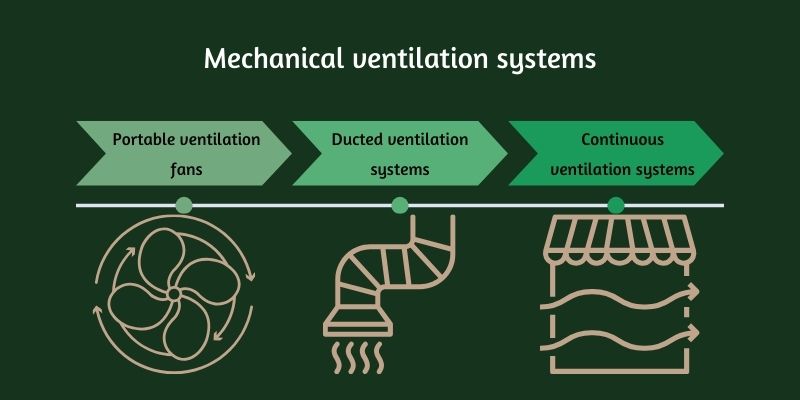

Mechanical ventilation systems

Mechanical ventilation systems are essential for maintaining air quality and promoting safety in confined spaces where natural ventilation is insufficient or impractical.

These systems utilize mechanical equipment to circulate air, ensuring adequate airflow and removing contaminants from the confined space.

Several types of mechanical ventilation systems are commonly used in industrial and commercial settings, including portable ventilation fans, ducted ventilation systems, and continuous ventilation systems.

Portable ventilation fans

Portable ventilation fans are versatile devices that provide supplemental airflow and ventilation in confined spaces.

These fans typically consist of a motor-driven impeller enclosed within a housing, which draws air in from the surrounding environment and expels it into the confined space.

Portable ventilation fans are commonly used for short-term ventilation needs or in remote locations where access to permanent ventilation systems may be limited.

One critical advantage of portable ventilation fans is their mobility and ease of deployment. They can be easily transported to different locations and quickly set up to provide immediate ventilation support.

Portable ventilation fans are available in various sizes and configurations to accommodate different confined space dimensions and airflow requirements.

Additionally, some models may feature adjustable speed settings or directional airflow capabilities, allowing for greater flexibility and control over ventilation operations.

Despite their portability, portable ventilation fans improve air quality and promote ventilation in confined spaces.

Introducing fresh air and removing stale air and contaminants, these fans help create a safer working environment for personnel inside the confined space.

However, it's essential to ensure proper placement and ventilation fan sizing to maximize effectiveness and avoid airflow obstructions.

Ducted ventilation systems

Ducted ventilation systems utilize ductwork to distribute airflow throughout the confined space, ensuring uniform ventilation and addressing specific airflow requirements.

These systems consist of a network of ducts connected to a central fan or ventilation unit, which draws in outside air, filters it if necessary, and distributes it to different confined space areas through strategically placed vents or diffusers.

One of the primary advantages of ducted ventilation systems is their ability to provide precise control over airflow distribution and direction.

By adjusting dampers or vents within the ductwork, operators can regulate airflow to different areas of the confined space as needed, ensuring adequate ventilation and maintaining consistent air quality throughout.

Ducted ventilation systems are commonly used in larger confined spaces or facilities where multiple work areas require ventilation support.

They are particularly well-suited for environments with specific ventilation requirements or where maintaining uniform air distribution is essential for worker safety and comfort.

Continuous ventilation systems

Continuous ventilation systems operate continuously to maintain consistent air exchange rates, providing long-term ventilation solutions for confined spaces that require ongoing ventilation support.

These systems are designed to operate continuously without interruption, ensuring a steady supply of fresh air and effectively removing contaminants from the confined space.

One key benefit of continuous ventilation systems is their ability to provide consistent ventilation performance over extended periods.

By operating continuously, these systems help maintain optimal air quality and prevent the buildup of harmful gases or contaminants within the confined space.

Continuous ventilation systems are often used when workers are present for extended periods, or uninterrupted ventilation is critical for maintaining safe working conditions.

Mechanical ventilation systems ensure adequate airflow and promote safety in confined spaces.

These mechanical solutions provide adequate ventilation support to safeguard worker health and well-being in various industrial and commercial environments, whether through portable ventilation fans, ducted ventilation systems, or continuous ventilation systems.

Training and Awareness for Confined Space Ventilation

Training and awareness are essential in ensuring the effectiveness and safety of confined space ventilation systems.

The Canada Safety Training Centre offers confined space training focused on educating workers on the importance of ventilation, providing instruction on the proper use and maintenance of ventilation systems, and outlining emergency procedures for ventilation failure.

Training for workers on the importance of ventilation

Practical training for workers on the importance of ventilation in confined spaces is essential for ensuring their safety and well-being.

This training educates workers about the role of ventilation systems in maintaining air quality and mitigating hazards within confined spaces.

Workers learn to recognize the signs of inadequate ventilation, such as stale air, odors, or hazardous gases, and understand the potential risks associated with poor ventilation, including asphyxiation, chemical exposure, and fire hazards.

In addition, a fire extinguisher course is crucial for workers to understand how to respond effectively to fire risks that may arise in confined spaces, ensuring they are prepared for emergencies.

By understanding the importance of ventilation, workers are better equipped to identify potential ventilation issues, take appropriate precautions, and communicate concerns to supervisors or safety personnel.

Additionally, confined space training emphasizes the need for workers to adhere to safety protocols and procedures related to ventilation, promoting a culture of safety and vigilance in confined space environments.

Instruction on proper use and maintenance of ventilation systems

Workers require instruction on adequately using and maintaining ventilation systems to ensure effective operation and longevity.

This instruction covers the correct procedures for operating ventilation and rescue equipment, including starting, stopping, and adjusting airflow as needed.

Workers also learn about the importance of regular maintenance tasks, such as cleaning filters, inspecting components for damage, and lubricating moving parts.

Proper maintenance helps prevent equipment malfunctions and ensures that ventilation systems operate efficiently.

Additionally, workers receive training on troubleshooting common issues with ventilation systems and how to address them promptly to minimize downtime and maintain a safe working environment.

Emergency procedures in case of ventilation failure

Workers need to be familiar with emergency procedures in the event of ventilation system failure to respond swiftly and effectively to potential hazards.

This training includes protocols for evacuating the confined space safely if ventilation becomes compromised and procedures for alerting supervisors or emergency personnel.

Workers also learn how to recognize signs of ventilation failure, such as sudden changes in air quality or unusual noises from ventilation equipment, and understand when to initiate emergency response measures.

By preparing workers with the knowledge and skills to respond to ventilation failures, organizations can minimize the risk of injury or harm to personnel working in confined spaces and ensure a timely and coordinated response to emergencies.

Final Words

Adequate confined space ventilation is essential for ensuring the safety and well-being of workers.

Mechanical ventilation systems, including portable ventilation fans, ducted ventilation systems, and continuous ventilation systems, are crucial in providing adequate airflow and removing contaminants from confined spaces where natural ventilation is insufficient.

Portable ventilation fans offer flexibility and mobility, making them suitable for short-term ventilation needs or remote locations.

Ducted ventilation systems provide precise control over airflow distribution, ensuring uniform ventilation throughout larger confined spaces or facilities with multiple work areas.

Continuous ventilation systems operate continuously to maintain consistent air exchange rates, providing long-term ventilation solutions for environments requiring ongoing ventilation support.

By utilizing these mechanical ventilation systems, organizations can create safer working environments and mitigate the risks of confined spaces.

Proper training and awareness programs are essential to ensure workers understand the importance of ventilation, know how to operate and maintain ventilation systems effectively, and are prepared to respond to emergencies in case of ventilation failure.

By prioritizing ventilation in confined spaces, organizations can protect their workforce, enhance productivity, and uphold regulatory compliance, building a workplace culture of safety and well-being.